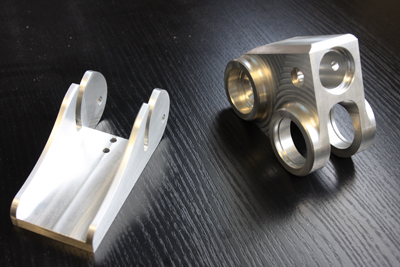

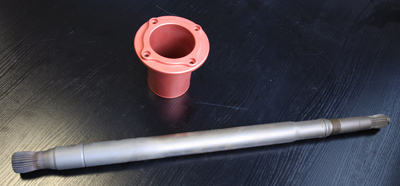

Precision mechanics and micromechanics machining

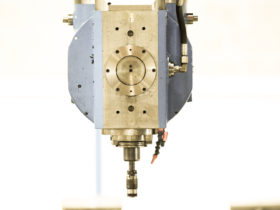

HERMES Technologies is a precision mechanics machining company. This is paramount for the manufacture of mechanical parts used through out our group. We have at our disposal 4 to 5 axis milling machines, 4 to 9 axis numeric controlled lathes, grinding machines, traditional machining units with three-dimensional control.

HERMES Technologies contributes to the group’s synergy by ensuring the high performance of CYBERMECA’s special machines mechanical parts and the reconstruction of machines with original parts by SRMO. Our machining autonomy gives us flexibility and responsiveness towards all other activities. We therefore guarantee timely and quality delivery.

Our services

HERMES Technologies manufactures complex parts in small or medium production volumes.

Our quality of service is highly valued by our customers in aerospace, aircraft, car and armament industries.

Equipped with a performing CAD/CAM system, customer plans can be programmed and transfered to our machining facilities.

Our skills and means of production

HERMES Technologies manufactures machined components using the means below :

Means of production :

- CAM MISSLER and MASTER CAM Programming

- 3, 4 & 5 axis machining centres

- 2, 3 & 9 axis turning machines

- Milling machines

- Cylindrical grinding machine

Methods of control :

- MMT3 Three-dimensional : Capacity : X=3000 ; Y=2500 ; Z=1000

- Marble dimension : 5000×3000

- ALTO Three-dimensional : capacité x=9000, Y=500, Z=400

- ROCK V2000 measurement column : Z=800

- MAHR measurement column : Z=550

- MMQ 10 Measuring station

Machines specifications :

| CENTRES D’USINAGE |

|---|

| C.U. 5 Axes : 5 AX 2000 Table capacity = 2100 X 1000 Machine courses : X= 2000, Y=1200, Z=600 Axe B = + ou – 110° Axe C = + ou – 183° |

| C.U. 5 Axes : HA- 5AX 7A Table capacity = 400 X 300 Machine courses : X= 570, Y=460, Z=410 Axe B = + ou – 110° Axe C = + ou – 360° |

| C.U. 4 Axes : MV 50 I Table capacity = 1100 X 610 Machine courses : X= 1020, Y=635, Z=610 |

| C.U. 3 Axes : OLY Table capacity = 1200 * 450 Machine courses : X= 1000, Y |

| C.U. 3 Axes : DEC Table capacity = 1600 * 600 Machine courses : X= 1170, Y=600, Z=500 |

| C.U. 4 Axes Horizontal bipalletisation : GSP Table capacity = 500 * 500 Machine courses : Z= 650, Y=390, Z=636 |

| TOURS NUMÉRIQUES |

|---|

| Tour numérique 9 Axes : TMM 250 Capacity : Chuck diameter = 300 Machining maximum length = 1600 Machine courses : X= 560, Y=260, Z=1600 |

| Tour numérique 4 Axes : RO Capacity : Chuck diameter = 225 Machining maximum length = 405 Machine courses : X= 195, Z=780 |

| Tour numérique 3 Axes : ER Capacity : Chuck diameter = 250 Machining maximum length = 790 Machine courses : X= 260, Z=790 |

| Tour numérique 2 Axes : TA Capacity : Chuck diameter = 315 Machining maximum length = 1000 Machine courses : X= 315, Z=1000 |

| BORING MACHINE – MILLING MACHINE AND TOWERS |

|---|

| GRAFFENSTADEN boring machine: Table capacity= 1500 X 1200 Machine courses : X = 2000, Y = 800, Z = 1000 |

| VERNIER FV3S milling machine : Table capacity : X = 1000, Y = 300, Z = 565 |

| BRIDGEPORT milling machine : Table capacity : X = 540, Y = 290, Z = 115 |

| SCULFORT Tower : Table capacity = 1000, Z = 2000 |

| PONAR Tower : Maximum diameter = 400, Z = 2000 |

| CAZENEUVE Tower : Maximum diameter = 385, Z = 685 |

| GRINDING MACHINES |

|---|

| EWAG WS 11 Precision grinding machine : Maximum diameter = 20, X = 100, Z = 100 |

| BILLETER Guideway grinding machine : Table 5000 X 1000, X = 5000, Y = 700, Z = 500 |

| BLOHM grinding machine : Table capacity 400 X 250 |

| BLOHM grinding machine : Table capacity 700 X 350 |

| TACCHELA outdoor cylindrical grinder : Maximum diameter = 250, entre pointes = 700 |

| C.C indoor & outdoor cylindrical grinder : Maximum diameter = 100, entre pointes = 900 |

| NOLAF indoor cylindrical grinder : Maximum diameter = 100 |